To maximize productivity, Six Sigma’s implementation decreases company variability and waste. Six Sigma is a problem-solving, high-performance approach to examining the causes of process variance and evaluating acceptable solutions, which is increasingly common in today’s world. How Can Six Sigma Help Companies Improve Quality and Productivity? Verify: Here, the team verifies the targets & results achieved through the newly designed process.Design: Here, the team documents the detailed process that meets the deliverables.Analyze: The teams will evaluate various process options here that will best meet the deliverables needed.Measure: Once the goals are identified, the team will measure the critical of its deliverable factors.Define: The project objectives and deliverables are defined here.There are five stages of the DMADV project methodology:

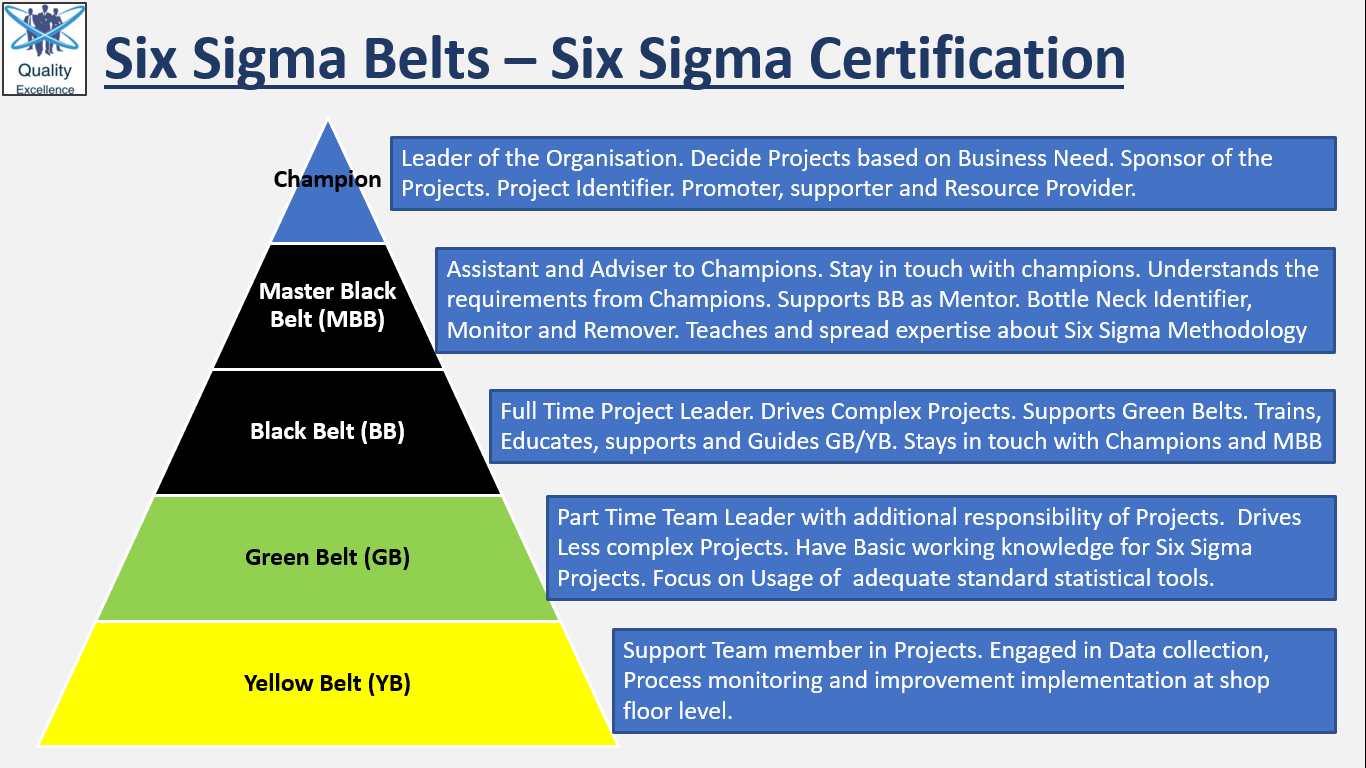

Six Sigma offers two main types of improvement processes. In the Quality Management team, depending on an individual’s role, Six Sigma requires a lot of training. The process of Six Sigma allows organizations to coordinate when it’s about regulating and enhancing quality. The criteria for quality enhancement and control standards are based on the explicit requirements of customers. Customer Focusįor the Six Sigma approach, the customer focus is fundamental. It is aimed at enhancing profitability and generating financial capital. In the Six Sigma method, the management needs some incentive to invest. In addition, Six Sigma is also objective-based. In order to get the best results, the procedure is flexible to fit the requirements and circumstances in which a project operates. This accentuates an essential feature of Six Sigma that is focused on facts and data.įor an organization’s project customized to its specifications and demands, the Six Sigma process is applied. The scientific basis of the technique is demonstrated by the statistical and systematic aspects of Six Sigma. The alternative method DMADV stands for Design-Measure-Analyze-Design-Verify. DMAIC is an acronym for Design-Measure-Analyze-Improve-Control. It features a well-defined methodical application approach in DMAIC and DMADV that can increase output quality. In theory, Six Sigma is not merely a quality management technique. Standard Deviation is used to quantify variance and is an essential method in terms of the output’s quality to measure non-conformance.

Six Sigma is explicitly derived from the Greek alphabet from the Greek letter ? (Sigma), denoting the Standard Deviation in Statistics. Characteristics of Six Sigma Statistical Quality Control

In this article, let us explore the six sigma methodology in detail. This increase in efficiency and decrease in process variance helps minimize errors and boost profits, employee productivity, and product or service quality. It provides tools for companies to enhance the potential of their business processes.

A process that performs at a 6 sigma level series#

Six Sigma is a creative and flexible series of methodologies aimed at improving organizational process quality and effectiveness.

0 kommentar(er)

0 kommentar(er)